Technological Importance of RFID Regardless Of Sector

According to Marc Van der Poll, network architect at Datacentrix of ICT solutions provider, Radio frequency identification (RFID) technology, a business with a warehouse storing r1 billion of goods is likely to encounter an annual stock loss of around r200,000 while the business may conduct an asset inventory once a year and this will take the full staff complement an entire week to complete technically unproductive time

“Without RFID, an automotive business with a warehouse storing R1 billion worth of goods, for example, would see an average annual stock loss of around R200, 000. The business may conduct an asset inventory once a year, which would take the full staff complement an entire week to complete – technically unproductive time. For the rest of the year, the organization relies on its accounting system to monitor what should be in the warehouse. However, this would most likely be inaccurate, as it would not detail the actual stock holding.”

Van der Poll also added that, because RFID needs no human intervention, stocking can be completed faster every week while ensuring that every issue at hand is identified and handled safely. But to handle this physically, asset inventory will be time-consuming since finding the barcode on each item will be slow as compared to RFID. “Asset inventories can be a time-consuming process as physically finding the barcode on each individual item can be slow going. With RFID, because it does not call for human intervention, stocktaking can be completed faster and more efficiently every week, ensuring that any issues are identified and dealt with”.

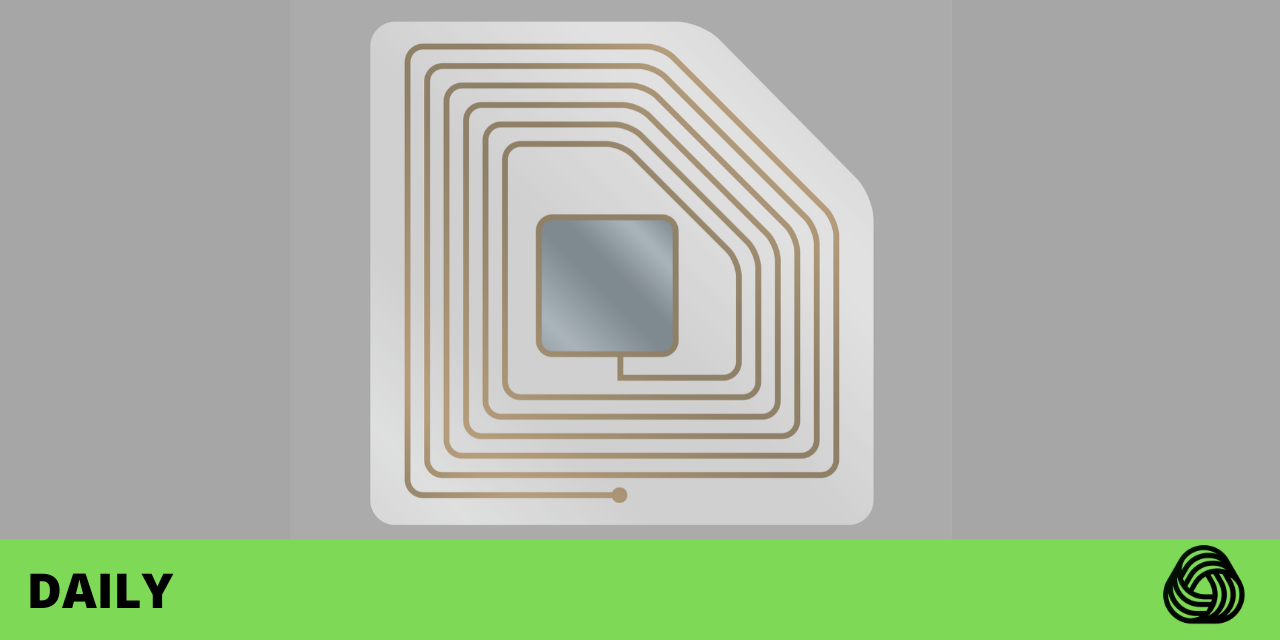

“RFID does not require line-of-sight, like bar code hand-held scanners, which are tricky to use as the operator needs to locate the bar code on the items. Instead, RFID technology allows you to count assets within seconds. Items are labeled using smart RFID tags, and either a hand-held scanner or an automated fixed-reader broadcasting a radio frequency every few seconds is used to ‘power’ these tags – meaning that they send out their information for capturing. This data is then fed into a back-end application.”

“Organisations could apply the same technique using a drone flying on a pre-determined path within a warehouse, quickly and easily checking and recording stock within a few hours.”

He believes with RFID, the retail industries will enjoy the fruit as well and will not be left out including the medical sector. “The technology can be used to send auto alerts of clothing on the floor, for instance, helping to track whether items in certain sizes need to be replenished from the stock room. It also alleviates the need to keep high levels of stock in-branch, as processes can be set up where oversupplies are moved between different locations as needed.

“From a field service management perspective, RFID offers an excellent solution with regards to in-the-field vehicles for the tracking of high-value tools and components – and not just limited to service and technical support related businesses. Emergency medical services (EMS) vehicles – such as ambulances, fire trucks, advanced responders and more – can harness RFID technology to keep track of expensive equipment. For example, a defibrillator that goes missing could cost the organization in the region of R400, 000. By tracking inventory items as they leave the vehicle, they are far less likely to be left on-scene, saving on wasted time linked to repeat site visits. Using washable RFIDs, gear and other clothing can also be tracked.”

“It also offers the ideal solution for weapon control, within the military as well as private security industries. RFID technology can not only be built into the weapons themselves, but also into weapon cabinets, to keep track of who is taking which firearms, and whether they have the requisite upfront approvals.”

Reference/ itnewsafrica